CEMENT-

, SCREEDS, AND MORTARS

Cement screeds and other mortars: controlling moisture and drying time during the construction phase

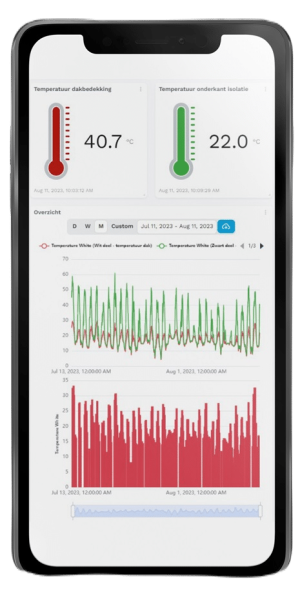

A cement screed must be solid, level, and dry enough before subsequent work can begin. But every floor dries differently—depending on the mixture, thickness, temperature, humidity, and construction phase. Inscio continuously measures moisture behavior without destructive measurements, so construction teams know exactly when they can safely continue building.

Why cement screeds are critical during the construction phase

A cement screed often seems like a controllable, predictable building component. In practice, however, this is precisely where a lot of delays, damage, or loss of quality occur. The biggest risks are:

- insufficient drying under finishes (PVC, parquet, tiles, carpet)

- invisible moisture accumulation due to diffuse behavior or high RH in the building

- ventilation and temperature that change daily, with a major impact on moisture transport

- accelerating the schedule while the floor is not yet dry enough

- damage caused by destructive measurements (CM measurements, drilling, cutting)

- cracking or loss of strength under unfavorable drying conditions

Because every floor reacts differently, a standard drying time is not a reliable starting point. Real-time monitoring reveals how the floor actually behaves.

What does Inscio measure?

What Inscio measures in cement screeds

Inscio continuously monitors the behavior of the cement screed—without breaking open the floor.

Moisture content in the floor

- measuring points at different locations

- understanding of moisture that slowly migrates upwards

- recognition of areas that dry significantly slower

Temperature and relative humidity in the room

- one of the most important factors for drying time

- immediate insight into the effect of ventilation, windows/window frames, finishing activities

Risk of condensation and mold

- detection of dew point conditions

- monitoring moisture load on floors, walls, and finishing layers

Typical risks associated with cement screeds

Inscio sees the same problems recurring in projects:

- The floor appears dry, but it is not → core moisture remains high

- Planning pushes for continued construction, resulting in premature completion

- Local areas remain wet (e.g., around facades, columns, cool corners)

- Ventilation is forgotten or depends on outside temperature

- Fluctuating RV due to construction activities such as plastering, painting, gluing

- Dew point problems lead to wet spots or delayed drying

Without continuous data, virtually all of this behavior is invisible.

- Inscio makes moisture behavior predictable, so construction teams don't have to guess whether the floor is dry enough.

How Inscio helps

Continuous insight into the drying process

Sensors measure moisture and temperature in and above the floor.

Automatic signaling

The software sends messages when drying is sufficient or risks arise.

Assess without damage

No drilling, cutting, or CM measurements—the floor remains intact.

Accelerating the dismantling process

Determine for each zone when you can safely start leveling, priming, or finishing.

Planning supported by data

Transparent towards clients, finishing contractors, and flooring suppliers.