Wood construction / CLT during operation

Wood construction / CLT in operation: maintaining quality, safety, and service life

CLT is strong, light, and durable—but remains sensitive to moisture, temperature fluctuations, and prolonged stress. During use, minor deviations can slowly develop into mold, delamination, odor problems, or structural risks. Inscio continuously monitors CLT so that owners know exactly how the material is behaving and where risks arise. This keeps the property healthy, safe, and valuable, from completion to the end of its life.

Why CLT can be risky during operation

Once a building is in use, the climate around CLT changes continuously: occupancy, ventilation, installations, seasons, and moisture flows influence the condition of the material. Many risks are not visible until damage has already occurred.

Common risks:

- Slowly increasing moisture content in CLT walls and floors

- Condensation in hidden places, especially during winter periods

- Mold growth in timber frames and connection details

- Delamination due to prolonged moisture or stagnant drying

- Fleeting odor problems caused by microorganisms

- Cold bridge condensation that only becomes visible after years

- Changing use of spaces (e.g., moisture production)

- Lack of insight during warranty period

Because CLT is often hidden behind finishes, problems only come to light when repairs are extensive and costly.

What does Inscio measure?

What Inscio measures in CLT during operation

Inscio investigates the behavior of the material itself, as well as the indoor climate that it influences.

Moisture content in CLT

- measurement points in core and surface

- detects rising trends that indicate risks

- distinction between short-term peaks and structural problems

Temperature and dew point

- understanding of conditions that cause condensation

- effect of fluctuating indoor and outdoor temperatures

Relative humidity and indoor climate

- relationship between resident behavior, installations, and moisture load

- insight into when rooms are structurally too damp

Construction zones & critical details

- connections with facade sections

- cavity

- floor-wall details

Typical risks that Inscio sees in CLT buildings

The same set of patterns emerges repeatedly from projects:

- CLT that slowly accumulates moisture, often due to micro-leaks or condensation

- Problems in wet areas (bathrooms, laundry rooms, kitchens)

- Increased moisture load due to user behavior or installation malfunctions

Monitoring allows these types of deviations to be detected at an early stage — well before any damage occurs.

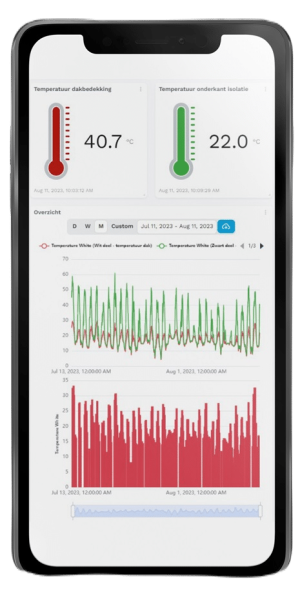

Visually

- Inscio transforms moisture management from ad hoc inspections to continuous risk management

How Inscio assists during operation

Real-time insight

Moisture and temperature are continuously measured and translated into clear signals.

Early warnings

The software identifies trends that indicate risks, such as rising moisture, stagnant drying, or structural condensation.

Substantiated maintenance

No unnecessary procedures, but interventions at exactly the right moment — just-in-time.

Security during the warranty period

Monitoring records how the CLT behaves from the moment of completion, which prevents discussions.

Limit risks of damage and loss of value

Timely intervention ensures that CLT elements remain healthy and functional.